Pickling Lines

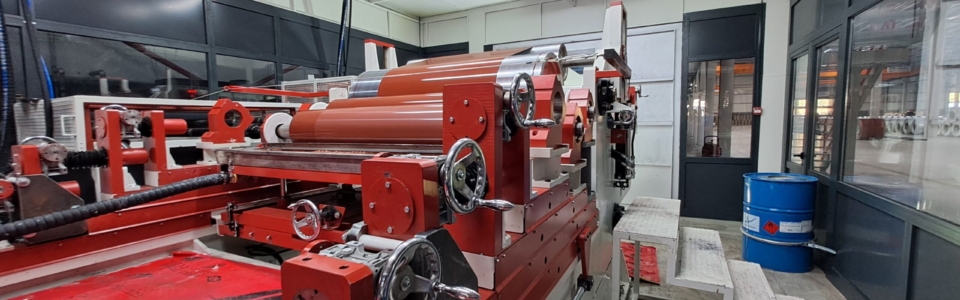

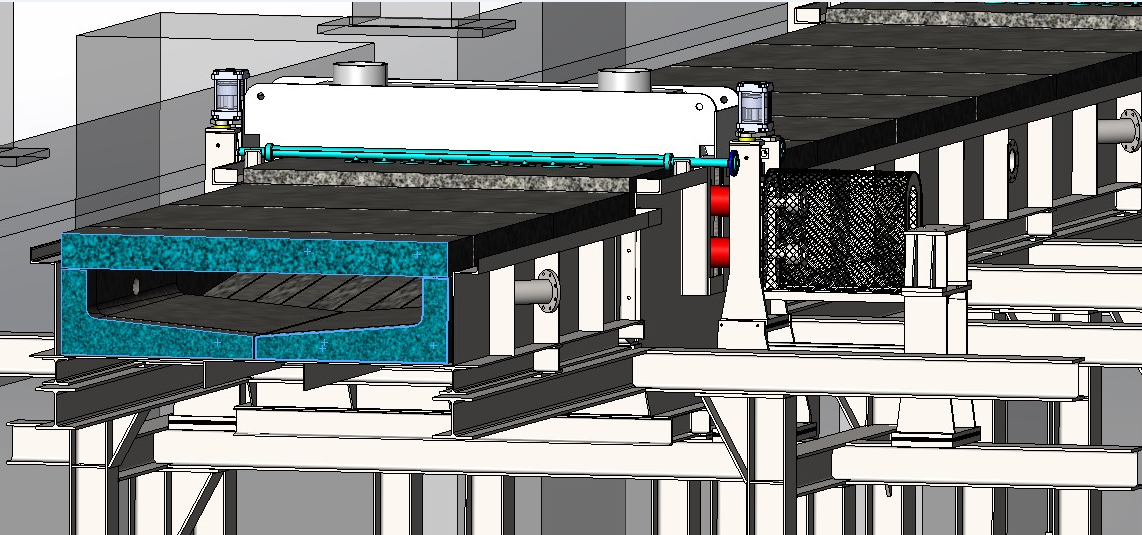

Push Pull Type Pickling Line

Continuous Pickling Line

In line with the demands of our customers, the pickling line is from inlet units to pickling process and output units;

- -Design,

- – Production,

- -Assembly and

- -Turnkey basis including commissioning.

- Uncoiler and Coil cars

- Anti coil breaking systems

- Straightening units

- Leveller Units

- Descaling systems

- Prewash units

- HCl acid processing units

- Rinsing and drying units

- Electrostatic lubrication units

- Shear units

- Scrap Removal Units

- Recoiler unit