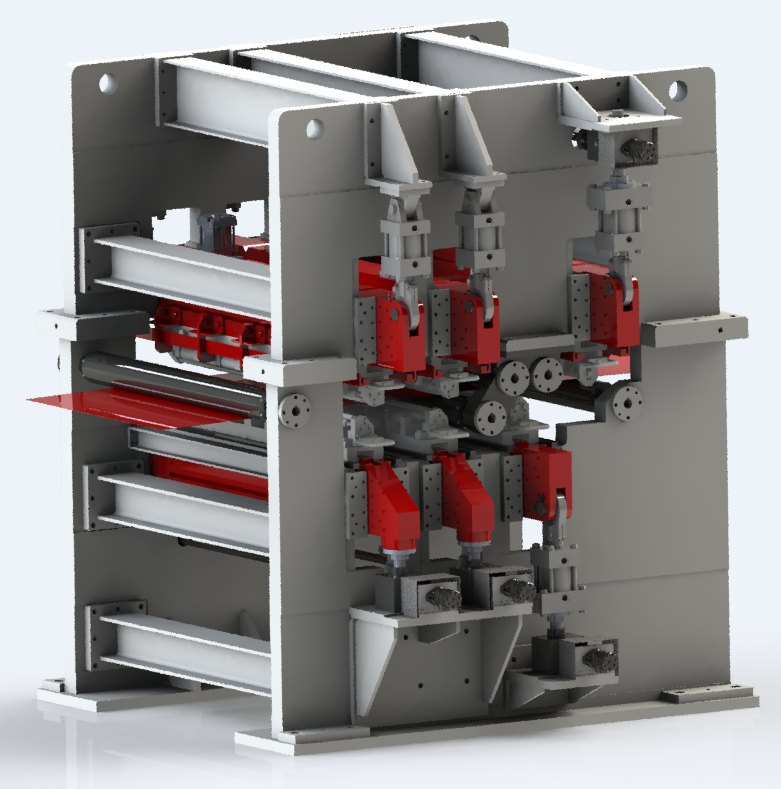

| Comissioning | 2020 |

| Material | Sıcak Çelik |

| Strip thickness | 1,5 – 8,0 mm |

| Strip width | 600 – 2000 mm |

| Maximum speed | 30 mpm |

| Threading speed | 15 mpm |

| Maximum coil weight | 32 ton |

| Shear Type | Start-Stop |

| Package weight | 8 ton |

| Stacker length | 8 m |

| Line length | 60 metre |

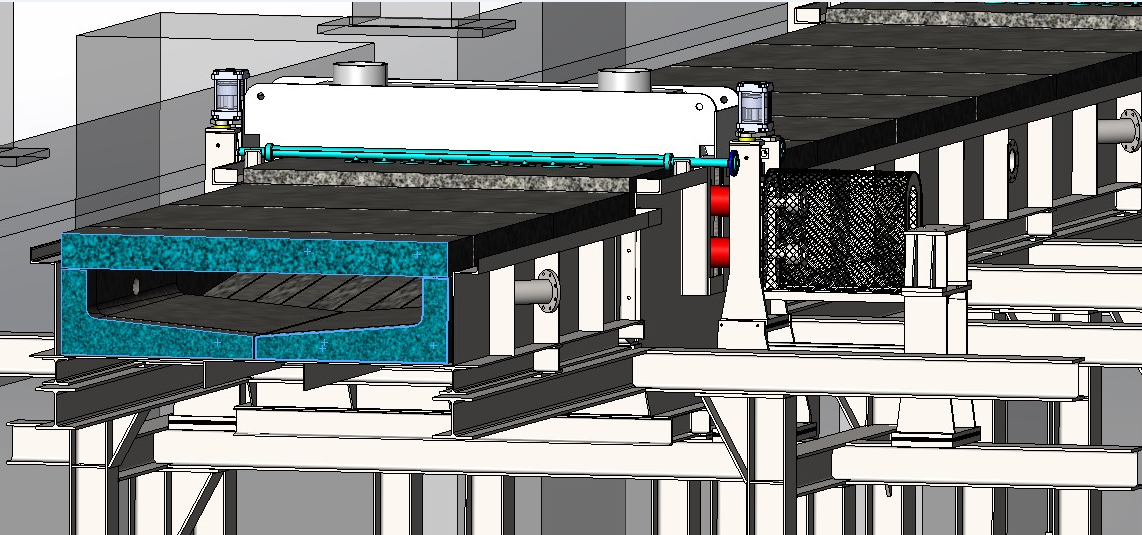

| Comissioning | 2022 |

| Material | Steel |

| Strip thickness | 0.3 – 2.50 mm |

| Strip width | 400 – 1650 mm |

| Maximum speed | 100 mpm |

| Threading speed | 25 mpm |

| Maximum coil weight | 25 tonnes |

| Shear Type | Rota-Fly |

| Package weight | 5 tonnes |

| Stacker length | 4 m |

| Line length | 50 metre |

We have developed coil inspection lines especially for detailed quality control of cold rolled coils after rolling. The quality controls of the sheet metal to be used in all sectors, especially in the automotive and white goods sectors, are carried out in accordance with international standards. The coil is opened by opener thru coil inspection line, a sample of the desired length is taken from the area where the quality control will be performed. The sample taken on the line is turned as the bottom face for quality control. Efficient lighting is also done for detail quality control. Thus, detailed quality control of both top and bottom surfaces of the coil sheet is provided.

We have developed special machines and provide processing services especially for the machining of roll housings in rolling mills. In the rail and profile rolling mill of Kardemir (Karabuk Iron and Steel Company), precise, high quality and efficient rail and profile production has been achieved by processing the rolling housings on-site machining and improving the bearing system. In addition, we successfully and timely completed the on-site machining of hot roll mill housings at Erdemir (Eregli Iron and Steel Company) and Toscelik companies

Especially in continuous coating lines such as color coating lines, tin chrome plating lines, the wavy strip is leveled by giving controlled elongation up to the plastic deformation limit. The system is designed as fully automated and the strip is leveled according to the wave condition and properties. In this way, the coating quality is increased and the products are produced in A1 quality. We have developed tension leveler system so that we ensure that the strip is of high quality and smoothness for coating by giving elongation at certain values in a sensitive and controlled manner and by giving proportional pressure to the rollers.

We have developed both hydraulic and mechanical levelers machines in line with the demands of our customers in order to straighten and level the incoming coils coming for cut to length lines or other lines with a high precision. With our leveler machines, leveling processes are carried out in laser cutting quality. Leveling systems are also supported by full automation systems.

In line with the demands of our customers, the pickling line is from inlet units to pickling process and output units;