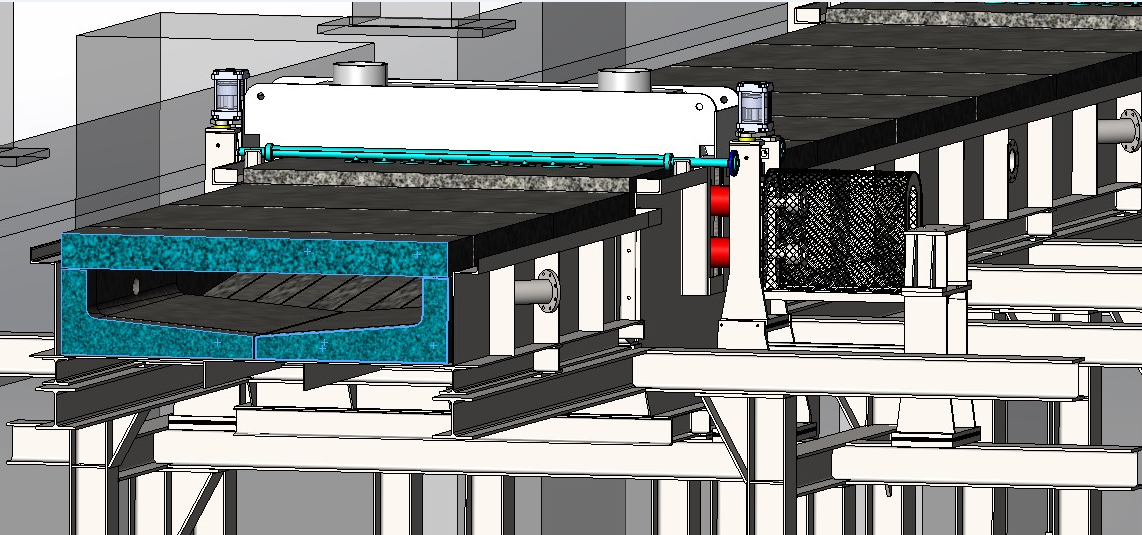

Coil Inspection Line

We have developed coil inspection lines especially for detailed quality control of cold rolled coils after rolling. The quality controls of the sheet metal to be used in all sectors, especially in the automotive and white goods sectors, are carried out in accordance with international standards. The coil is opened by opener thru coil inspection line, a sample of the desired length is taken from the area where the quality control will be performed. The sample taken on the line is turned as the bottom face for quality control. Efficient lighting is also done for detail quality control. Thus, detailed quality control of both top and bottom surfaces of the coil sheet is provided.

Projects Made

Pickling Lines

Push Pull Type Pickling Line

Continuous Pickling Line

In line with the demands of our customers, the pickling line is from inlet units to pickling process and output units;

- -Design,

- – Production,

- -Assembly and

- -Turnkey basis including commissioning.

- Uncoiler and Coil cars

- Anti coil breaking systems

- Straightening units

- Leveller Units

- Descaling systems

- Prewash units

- HCl acid processing units

- Rinsing and drying units

- Electrostatic lubrication units

- Shear units

- Scrap Removal Units

- Recoiler unit

Ongoing Projects

Cut to Length Lines

We make complete turnkey high speed and quality cut-to-length lines including Design, Project, Manufacturing, Assembly and Commissioning.

- Cold Cut-to-Length Lines

- Hot Cut-to-Length Lines

- Uncoiler and Coil Cars

- Automatic roll loading units

- Quick cutting shear units

- Hydraulic or mechanical straightening machines

- Pinch Rolls

- Rotary Shears

- Automatic Blade Adjustment System

- Automatic Stacking Units

- Full automation systems

Projects Made

Continuous Coil Color Coating Lines

We Produce Continuous Coil Color Coating Lines…

We determine the design parameters by considering the strip type and quality, thickness, width and production capacity according to customer demands. We design, manufacture, assemble and turn-key all the facilities of the continuous coil color coating line from the input units to output units.

Our lines are controlled by modern control systems, mainly using Siemens products. The production line is monitored and controlled by the operators with the SCADA screen. We also have Level-2 Software to cooperate with ERP systems and to direct the control system of the line, to follow the coils, to collect the data of the product and the line.